Qingdao CHUANGYU specializes in CNC machining for precision mechanical parts, offering a wide range of surface treatment options to enhance the durability, appearance, and performance of both CNC machined and sheet metal parts. In China, CNC machining manufacturers commonly employ various surface finishing techniques, including sandblasting, anodizing, electroplating, polishing, wire drawing, oil injection, paint spraying, quench polish quench (QPQ), physical vapor deposition (PVD), electrophoresis, and electroless nickel plating. Below, we provide an overview of these surface treatments.

1. Sandblasting

Sandblasting is used to remove machining marks and create a uniform surface fini

sh on CNC machined parts and sheet metal components. By applying fine glass beads, this technique covers any knife patterns left from machining. Sandblasting is often performed before anodizing, as it enhances the final appearance of the anodized product.

2. Anodizing

Anodizing is a surface treatment process primarily used for aluminum CNC parts and sheet metal components. This process enhances the surface hardness, wear resistance, and aesthetic appeal of the parts. Anodizing is available in various colors, such as yellow, gold, red, green, black, and more. It’s widely applied in industries like automotive, electronics, and optics.

3. Electroplating

Electroplating is one of the most common surface treatment methods for CNC machined and sheet metal parts. By coating the surface of iron or steel components with zinc, chrome, gold, silver, or nickel, electroplating protects against rust and corrosion, making it ideal for parts used in automotive, mechanical equipment, and instrumentation applications.

4. Polishing

Polishing involves the use of mechanical, chemical, or electrochemical techniques to reduce surface roughness and achieve a shiny, smooth finish. This method is typically applied to aluminum, steel, and titanium alloy parts to enhance their visual appeal and smoothness.

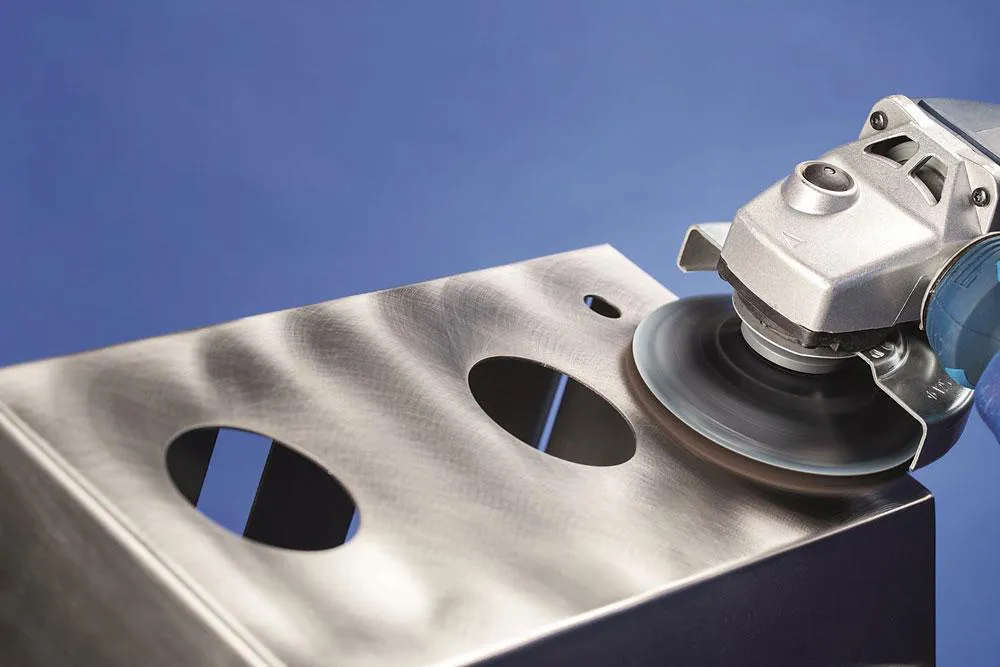

5. Wire Drawing

Wire drawing creates decorative lines on the surface of CNC machined and sheet metal parts through grinding. This technique is commonly used on steel and aluminum products to add a visually appealing texture to the surface.

6. Oil Injection

Oil injection is a coating method where atomized paint is sprayed onto the surface of CNC metal or plastic parts using spray tools like spray guns. This process is often used for consumer electronics, beauty instruments, and handheld measuring devices to provide a protective and decorative coating.

7. Paint Spraying

Paint spraying is typically employed for larger CNC precision parts and sheet metal components. It serves as a protective layer that prevents rust and corrosion, making it suitable for chassis, automotive parts, automation equipment, and forklift products.

8. Quench Polish Quench (QPQ)

QPQ is a specialized metallurgical process where CNC metal parts are treated in two different salt baths to form a composite infiltration layer on the surface. This layer significantly improves wear resistance, corrosion resistance, and fatigue strength, making QPQ ideal for engine components, gears, spindles, and other high-performance parts.

9. Physical Vapor Deposition (PVD)

PVD coating technology creates a thin film layer on the surface of parts, offering high hardness, wear resistance, and excellent aesthetic qualities. Available in a range of colors, PVD is commonly used for decorative and functional purposes in locks, automotive accessories, and hand ornaments.

10. Electrophoresis

Electrophoresis involves coating CNC parts with a smooth, uniform layer of material through an electrochemical process. This technique is suitable for various materials, including copper, aluminum, and stainless steel, and is widely used for products like auto parts, optical accessories, and radiators.

11. Electroless Nickel Plating

Electroless nickel plating is a chemical process that coats CNC parts with a nickel layer, offering enhanced corrosion resistance and prolonged service life. This surface treatment is commonly used in the manufacturing of automation equipment, mechanical parts, and packaging machinery.

Conclusion

At Qingdao CHUANGYU, we offer a comprehensive range of surface treatments to meet the specific needs of your CNC machined and sheet metal parts. These treatments not only improve the functional properties of the components but also enhance their visual appeal, ensuring that your products are both durable and aesthetically pleasing. Whether you need sandblasting, anodizing, or any other surface finish, our advanced facilities and experienced team are equipped to deliver top-quality results.